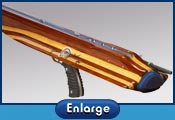

WOOD STOCK

My guns are constructed and created

in the style of the traditional Australians and South

African spear guns.

Based on professional experience,

I firmly believe that wood lamination gives the wood assembly

more strenghth and durability then that of single wood

stock.

That

is why I choose to make the guns using laminated aged

Burmeese Teak and accented it with Ash for increased strength

and aesthetic appearance.

That

is why I choose to make the guns using laminated aged

Burmeese Teak and accented it with Ash for increased strength

and aesthetic appearance.

Starting with selected dense,

straight grain stock plank (aged well over 20 years) and

going through the following processes:

Planed down to size, additionally

cured, laminated and glued in opposite grain directions

to increase stability.

After  machining

all profiles, contours and radiuses, the stock is hand

carved and sanded to the desired shape and dimensions.

machining

all profiles, contours and radiuses, the stock is hand

carved and sanded to the desired shape and dimensions.

Then the wood stock is saturated

in 3 consequent steps with liquid epoxy sealer. Followed

by hand sanding between applications with fine sand paper

to achieve perfectly smooth surface finish.

For the final protective finish,

the stock is coated several times with a marine Envirotex

UV-Epoxy that creates a long-lasting hard coat finish.

All the hardware, muzzle, handle,

reel etc., are then mounted and assembled into the spear

gun stock. Finally, after balancing, the product is complete.

Unlike most manufacturers, my spear guns come

pre-balanced and ready to use!

GUIDE TRACK

My

spear guns are made with a fully encapsulated polyethylene

guide track assuring accuracy, noise reduction and eliminating

spear vibration.

My

spear guns are made with a fully encapsulated polyethylene

guide track assuring accuracy, noise reduction and eliminating

spear vibration.

The guide tracks are machined

from Polyethylene material known as Tivar®*. This

material provides specific versatility, not found in any

other industrial polymers. It has characteristics which

make it much more durable and superior to any other materials

used by spear gun producers.

Tivar

has one of the lowest co-efficients for friction (0.12)

which is very close to Teflon (0.08) and much less then

that of Delrin (0.32) – the one wildly used in making

custom spear guns. Tivar displays excellent high shock

strength, has high-abrasion resistance and outwears steel

6 to 1. It is chemical resistant, non-absorbent and assists

smooth flow.

Tivar

has one of the lowest co-efficients for friction (0.12)

which is very close to Teflon (0.08) and much less then

that of Delrin (0.32) – the one wildly used in making

custom spear guns. Tivar displays excellent high shock

strength, has high-abrasion resistance and outwears steel

6 to 1. It is chemical resistant, non-absorbent and assists

smooth flow.

*Tivar® is a registered

trademark of Menesa Corporation.

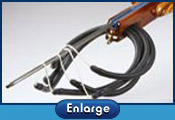

MUZZLE

Every

one of my spear guns are equipped with a built-in reinforced

stainless steel muzzle. Constructed from laser cut 1/4"

thick stainless steel plate to provide additional support

and strength to the rubber band's channel. This allows

adding more bands without effecting the structural integrity

on the wood stock.

Every

one of my spear guns are equipped with a built-in reinforced

stainless steel muzzle. Constructed from laser cut 1/4"

thick stainless steel plate to provide additional support

and strength to the rubber band's channel. This allows

adding more bands without effecting the structural integrity

on the wood stock.

The muzzle also has an added extension

wich can be used as an anchoring point on the shooting

cable – used in competitions or commercial spear

fishing.

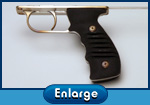

HANDLE

The

gun handles I make are the only ones constructed in stainless

steel. The handle frame was laser cutted 1/4" stainless

steel plate with added side grips. These side grips are

crafted from rock-hard commercial grade Buna-N-Rubber

black rubber with a hardness durometer of 70. The handle

shape was designed and created in a manner to provide

a more friendly and anatomically/ergonomical feeling.

The side grips are cut from solid rock hard rubber plate

then individually carved and sculpted until reaching the

desired comfortable hand/palm feel.

The

gun handles I make are the only ones constructed in stainless

steel. The handle frame was laser cutted 1/4" stainless

steel plate with added side grips. These side grips are

crafted from rock-hard commercial grade Buna-N-Rubber

black rubber with a hardness durometer of 70. The handle

shape was designed and created in a manner to provide

a more friendly and anatomically/ergonomical feeling.

The side grips are cut from solid rock hard rubber plate

then individually carved and sculpted until reaching the

desired comfortable hand/palm feel.

Specially designed slip-resistant grooves

are machined on the sides of the rubber grips.

TRIGGER

For the trigger mechanism on the spear

gun I chose the Alexander trigger. This mechanism is proven

to be superior for its durablilty, strength and handling.

It

is very light, short trigger pull, assuring smooth operation,

which is essential when using multiple-band high-power

spear guns.

It

is very light, short trigger pull, assuring smooth operation,

which is essential when using multiple-band high-power

spear guns.

The trigger mechanism manufactured

by Alexander comes with a lifetime guarantee against defects

or failure during normal usage with properly-matched spear

shafts.

Alexander's modular design trigger

mechanism is constructed from solid 316 grade stainless

steel providing exceptional performance.

This is quite a difference from

the press punch formed sheet metal trigger devices used by many "big name"

mass production manufacturers.

SPEARS

The spear shafts by Mori are made

from 17-4 grade spring Stainless Steel and heat treated

to a hardness of 46 Rockwell. The shafts are threaded

with a 5/16" x 24 fine threads to accept the spear

tips or spear tip adapter.

All

5/16" diameter shafts are equipped with 3 cocking

tabs (fins) for loading the rubber bands wish bone cords.

The 3/8" diameter shafts are equipped with 4 cocking

fins for the additional bands on the longer/larger guns.

All

5/16" diameter shafts are equipped with 3 cocking

tabs (fins) for loading the rubber bands wish bone cords.

The 3/8" diameter shafts are equipped with 4 cocking

fins for the additional bands on the longer/larger guns.

Mori's shafts are specially manufactured

with precision in straightness (capable of reaching maximum

deviation of .005"). Results like this are non-existent

in the process used by other manufacturers.

SIDE STOCK WINGS/STABILIZERS

The

Channel/Island spear gun (58"), Performance (60"), and

Blue Fin (65") guns are constructed with permanently attached,

specially designed side stock (delta wing) stabilizers.

The

Channel/Island

(58") spear gun is equipped only with front muzzle

(delta) wing side stabilizer. This wing design provides

more stability and (at the same time) aligns the power

bands in parallel line with the spear shaft. The

Channel/Island

(58") spear gun is equipped only with front muzzle

(delta) wing side stabilizer. This wing design provides

more stability and (at the same time) aligns the power

bands in parallel line with the spear shaft. |

Performance

(60") and Blue Fin

(65") guns are constructed with the same front muzzle

(delta) wing and a specially profiled rear stabilizing

wing stock in order to improve stability and accuracy. Performance

(60") and Blue Fin

(65") guns are constructed with the same front muzzle

(delta) wing and a specially profiled rear stabilizing

wing stock in order to improve stability and accuracy. |